A short overview of the core Bionic Technologies:

The Bionic µfuel Technology (microfuel)

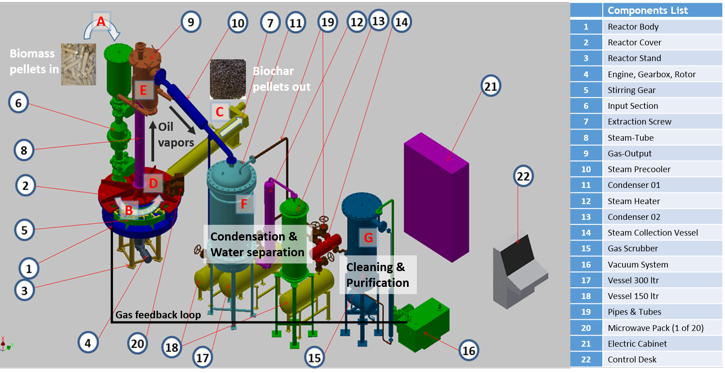

The Bionic µfuel technology offers a wide range of possible applications. An extremely versatile rotary, fixed bed microwave reactor offers a high level of phased control over microwave power applied, time of treatment and reaction mass heat levels, controllable by a highly sophisticated set of electronic sensors and a computerized control system. The gas atmosphere and pressure within the reactor vessel can be adjusted to the feedstock requirements from a near vacuum to a moderate over pressure.

Due to a fully contained reactor and processing design, emissions from a commercial plant are limited to the cleaned flue gas from the generator (CHP) exhaust.

Some areas of application:

-

Biomass to fuel with different types of feedstock like miscanthus, eucalyptus, jatropha, castor, bamboo, maize, sugar cane or wood chips, press cake of rape seed or olives and bagasse are only a few examples.

-

The microfuel technology does not depend on food crops like the bio-ethanol production but is ideal to convert biomass waste into fuel. Therefore, there is no competition with the food market. Depending on the specific energy content of feedstock, biomass oil yields can be expected between 30 and 45%.

-

Fuel from municipal solid waste like garden waste, wood residues, food and demolition materials (with the exception of PVC fractions).

-

Fuel from industrial waste like plastic foils, other plastic and textile waste, HCF.

-

Fuel from asphalt building materials and any oil containing waste.

-

Fuel from used tyres without the necessity to first remove steel and textile fractions.

-

Fuel from used oils in combination with biomass or plastic fractions.

-

Recovery and cleaning of toxic oil and solvent residues from contaminated soils.

-

Clean, environmentally friendly extraction of crude oil from tar sand and oil shale.

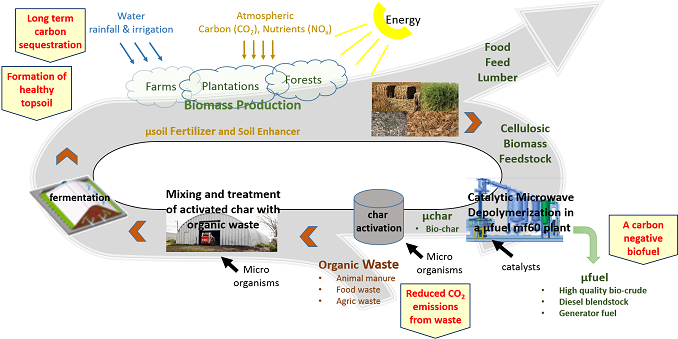

The liquid product phase, the Bionic µcrude can be used directly as a fuel for stationary power generators or a blendstock for traditional refineries. Alternatively it can be upgraded to match international standards for transportation fuels. The secondary product, Bionic µchar has a very high calorific value as a solid fuel, similar to antrazite and is usable for power-generation or it can be biologically upgraded for the use as an organic fertilizer and soil enhancer. For this purpose, Bionic has developed its unique µsoil product.

A standard µfuel plant typically consists of:

-

material storage

-

feedstock preprocessing (graining and pelletizing)

-

microfuel disintegrator (available from 1 to/hr to 20to ++ / hr input capacity

-

crude oil condensation and vacuum system

-

fuel distillation, processing and upgrading (desulphuring & stabilization)

-

residue handling (char cooling & storage, waste water processing)

-

power generation (generators for power supply)

-

tank farms

-

laboratory

Plants can be designed for any feedstock capacity by clustering the standard mf480 reactor in groups of 4.

Read more about Bionic µfuel...

Bionic µsoil - microbial activation of Bionic's µchar product

From the beginning of 2013 Bionic concentrated on the best way to turn µchar, a high quality biochar deriving from the µfuel process when biomass is used as feedstock, into a modern soil enhancer and organic fertilizer.

The µsoil cycle: fixing carbon in the ground

The result is a new innovative product, globally unique, called Bionic µsoil. Bionic µsoil can be characterized as the Terra Preta of modern times, produced in a short time span of few weeks and in a scientifically controlled biotechnology process - compared to many years of natural ripening of its ancient ancestor.

Read more about Bionic µsoil...

Bionic µCTL carbon liquefaction

Based on the successful µfuel development Bionic entered also into the field of carbon liquefaction or CTL. In 2012 Bionic announced its new microwave assisted coal liquefaction process which greatly improves the nearly 100 year old Bergius direct coal liquefaction process. Bionic implemented the process with a new reactor design from the ground up combining microwave radiation with high pressure hydration in a single reaction vessel. Several patent applications are pending on this break-trough technology which has enormous potential as it makes CTL a clean and energy efficient technology.

This new µCTL process can not only be used to efficiently convert fossil coal into liquid fuels like heavy oil, diesel, gasoline and jet fuel. The process works also with the char fractions produced by pyrolysis techniques from all kinds of carbonaceous feedstock like biomass, municipal and commercial waste streams, used tires and more.

An especially attractive application is the combination of Bionic’s own µfuel MWDP process with this new microwave CTL technology. A combination which implies a long list of cost saving synergies on both process stages.

Bionic µCTL was designed to be combined with a coal gasification method called devolatilization producing a quality gaseous fuel product and a coke residue which then becomes the feedstock for a second stage Bionic µCTL plant. Both methods together are making coal a very clean source of energy while at the same time greatly improving its energy efficiency.

Read more about Bionic µChar...