10 YEAR ANNIVERSARY ON BIONIC LABORATORIES BLG GmbH, 15 YEAR ANNIVERSARY OF BIONIC GROUP in 2021

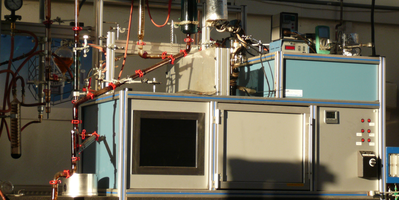

Bionic is the global leader in commercial microwave applications for energy conversion technologies. Feedstock like biomass, plastic waste, scrap tires as well as refinery residues are converted into high value raw materials. In Bionic's systems microwaves interact with high-tech catalysts for the production of oil and char fractions usable not only as renewable enb