10 YEAR ANNIVERSARY ON BIONIC LABORATORIES BLG GmbH, 15 YEAR ANNIVERSARY OF BIONIC GROUP in 2021

Bionic is the global leader in commercial microwave applications for energy conversion technologies. Feedstock like biomass, plastic waste, scrap tires as well as refinery residues are converted into high value raw materials. In Bionic's systems microwaves interact with high-tech catalysts for the production of oil and char fractions usable not only as renewable enb

.

.

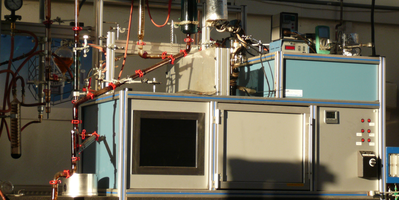

The mf60 demonstration plant mid 2013 ..and in April 2014 after some modifications ready for certification.

Bionic’s Catalytic Microwave Depolymerization Process (MWDP) effectively takes pyrolysis to the next level. It stands out as the only microwave assisted pyrolysis process that is ready for commercial use, but it also integrates zeolite catalysts as a further enhancement to gain better control of the process. The many innovative details in the hybrid technology coupling microwave with zeolite catalysts produce a level of quality in liquid and solid fuel products unmatched by any other comparable process.

MWDP stands out as the flagship activity within the Bionic group. With the Bionic µfuel series of energy conversion plants Bionic is the global technology leader in the use of microwave applications for alternative fuel production.

The Bionic µFuel technology works at temperatures below 350°C. The resulting light oils (µCrude) can be used as a generator fuel, blendstock or further upgraded to standard diesel and jetfuel. In addition a valuable dry µChar is produced. It has excellent high-calorific properties and can be used for various biochar applications, from solid fuel to a carbon sequestering soil amendment or activated carbon. Bionic has developed its own µChar based organic fertilizer and soil amendment, Bionic µSoil, which is able to recapture large quantities of carbon from the atmosphere for thousands of years. In fact, this product makes the complete Bionic µFuel process carbon negative when used for biomass feedstock.

A related liquefaction technology (µCTL) converting coal, such as lignite or char residues from µFuel and gasification process into liquid fuels is also under development.

Typical µfFel plants have a capacity per hour of up to 4 tons of dry biomass or 2-4 tons of MSW high calorific fractions. Feedstock is converted to 1-2 tons of liquid fuel per hour. Processing of high calorific plastic & tire waste may result in significantly higher liquid yields compared to biomass. Adapted µfuel technology allows also the processing of oil sludge from refinery residues and the decontamination of oil-polluted soil. The smallest decontamination units can be installed in standard flip-containers for mobile use.

The Bionic µfuel technology has been developed over many years and large numbers of different feedstock have been tested successfully on the laboratory level. Compared to other depolymerization systems offered µfuel has numerous advantages resulting in higher yields, extremely low catalyst consumption (<0,5%) and significantly better oil quality than all other commonly known pyrolysis systems. Custom designed, extended lifetime microwave units supporting the HF field modulation components specifically developed for µFuel's "in-the-pellet micro reactors", transforming feedstock into hydrocarbons in a single step pathway make all the difference.

µFuel systems are now available in various sizes, ranging from 1,000 ltr. µcrude output per hour up to clustered systems with more than 20,000 liters/hour capacity.

Around the microfuel system several cutting edge technologies have been developed by Bionic R&D:

-

redundant vacuum systems to achieve optimal vacuum levels

-

desulfurization systems, using ionic salts, for upgrading to ultral-low-sulphur fuel

-

distillation systems for separation of phenols and organic acids from biocrude

-

effective microwave driven, biomass fed hydrogen generators

-

microwave driven hydrotreaters for oil stabilization

-

microwave driven liquefaction reactors for lignite char or coal to fuel processing

-

adaptation of solid state microwaves are in development for significantly longer lifetime and less maintenance

Competent partners, sales agents and project customers are welcome to help improve the overall impact of our technologies.

Investors are invited to join our global network and trusted manufacturers to participate in our leading edge manufacturing platforms.

Our latest corporate video can be viewed here

Visit us at our Facebook Page for the most recent news articles and pictures...

Feel free to contact us with any questions you might have:

This email address is being protected from spambots. You need JavaScript enabled to view it.

![]()

Bionic Laboratories BLG GmbH

Spessartstr. 13

D-64851 Eppertshausen

Germany

Phone: +49 1525 3340 500