Main applications for the Bionic µfuel technology

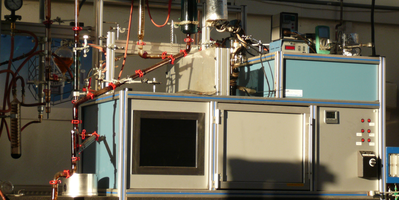

The Bionic µfuel technology is extremely flexible in terms of feedstock, treatment and product mix. This flexibility is primarily due to the unique reactor design which allows great variation of the microwave application (power, modulation, pulse) over the whole treatment period. The reaction atmosphere is variable from using a gaseous phase feedback loop to the supply of an inert gas of choice. Usually the reactor operates as a reduced pressure cycle which can also be controlled by the vacuum pump.

For commercial applications a number of feedstock groups have been defined. While the overall processes can vary greatly in terms of feedstock preparation, core treatment parameters and product mix, quality and yield, in all cases hydrocarbon vapors are extracted from the reaction mass using microwave energy and further treated as required for the intended end products.

Volatile hydrocarbons (gas phase) are usually used internally to produce part of the required energy.

Biomass

This group includes all types of organic waste and energy crops. Organic waste cannot only derive from agriculture, forestry and horticulture, but includes also food waste and the waste products from many industrial processes like biogas facilities, palm oil mills and much more. Lignocellulosic biomass feedstock (wood, straw, energy grasses like miscanthus) is the one with a higher energy content. It derives from "waste" sources as well as dedicated energy crop plantings.

Municiple Solid Waste (MSW) and Industrial Waste streams

The world produces enormous amounts of waste every day most of which is still unmined for its potential in recycling and energy. Bionic µfuel converts most of the carbonaceous fractions. The most atractive are the high caloric fractions of plastics, textiles and paper, also called refuse derived fuels or RDF.

Scrap Tires

Large deposits of used tires can with tens of millions of pieces can be found around the globe. This is not only a waste of resources but also a huge health and fire risk. The µfuel process can easily separate the contained scrap metal and convert the remainder in gaseous, liquid and solid fuel fractions. Processing of scrap tires is the least challenging application of our process and highly profitable.

Soil Decontamination and Fossil Hydrocarbons

In the traditional oil industry a lot of contamonation has occured over the years, very often causing decades of negative consequences especially for water resources. The µfuel technology has a unique capability to extract oil spills from all kinds of ground including beaches. However, it is also a much more efficient technology to process tar sands and oil shale than those applied today.